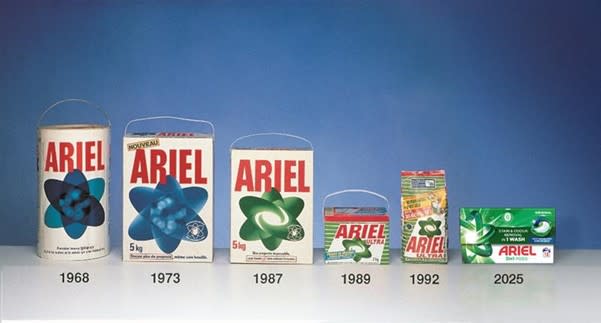

In years past, doing laundry often meant contending with heavy, bulky boxes or large bottles of detergent that took up valuable storage space. However, over time and thanks to ongoing innovations in the industry, the landscape of laundry detergents has changed significantly. The shift towards product reformulation and compaction has allowed to replace those giant packs with sleeker, more compact and smaller packaging.

The laundry detergent you see on the shelves today tells a story of scientific advancement and smarter cleaning methods that have evolved over decades.

Are detergent packs smaller now?

If we take a step back 30 or 40 years, laundry detergents were quite different. They required a larger quantity of ingredients to achieve effective cleaning results, leading to bigger packs and higher doses per wash.

As scientific innovation progressed, laundry detergent brands developed, more efficient cleaning technologies, enabling them to deliver excellent cleaning results with significantly smaller quantities. Today’s detergents can offer the same number of washes as their predecessors but with much lower product volumes, all without compromising on cleaning standards.

Modern detergent packs now feature clear dosing instructions as per European regulation, and many include simple dosing devices to ensure the correct amount is used. Products like Ariel PODS® have simplified the process even further by offering an easy-to-use, single-unit dose. All compact detergents are designed to deliver excellent results on the first wash, using the appropriate dose.

More powerful cleaning with less environmental impact

Innovations in laundry detergents have been ongoing for over 20 years. From 1997 to 2017, the European Laundry Detergents industry collectively saved around 30 million tons of detergents, despite a 23% increase in wash-loads across Europe*. This represents 45% in total detergent consumption. This also means an important decrease of the packaging used - up to 240.000 tons, which is enough to fill 20.000 waste collection trucks - and an estimated 1.4 million tons of CO2 savings*.

This remarkable achievement was made possible by reducing the dosage required for a single wash load by almost half. The recommended dosage decreased from 150 grams in the late 1990s to less than 75 grams for powders and from 150ml to less than 55 milliliters for liquids*. This reduction is possible thanks to the compaction made possible by more effective formulations and ingredients. The trend towards product downsizing and smaller packaging continues today, offering benefits beyond just the convenience of handling smaller packages.

Compaction: less is more!

Despite the advantages of smaller packaging and compact products, a common misconception persists: are these products still good value?

The most effective way to compare detergents is by looking at the number of washes each pack or bottle delivers. Every detergent package displays this information, typically indicated by a basket icon containing a number. This allows consumers to easily identify the average number of wash loads per pack. When comparing detergents, focus on the number of washes rather than milliliters or grams.

Product reformulation explained: the secret behind compact detergents

Among the many innovations that made prcompaction product possible, the evolution of enzymes stands out as a key enabler. These specially designed cleaning actives effectively target and tackle tough stains, even in cooler water. Enzymes are cleaning ingredients thatbreak up a piece of dirt and move on to the next – continuously working from the start of the wash till the end. Therefore, only a small amount is needed to achieve impeccable results, replacing larger volumes of traditional ingredients with enzymes, resulting in compact products that deliver impressive cleaning performance.

Over the years, new generations of enzymes were designed to work better at lower temperatures to respond to new consumer trends in laundry habits, fabrics and sustainability insights. This development makes them crucial for compaction and product reformulation, as well as a key enabler for lowering wash temperature, saving energy and reducing CO2 emissions. A prime example of this innovation is the Purezyme technology used in Ariel, inspired by enzymes found in seaweed.

Additionally, traditional actives in detergents – surfactants – have evolved to become more efficient. Modern detergents typically contain well designed blends of surfactants that act in synergy to be more efficient on a wider range of greasy substances, in many different conditions, including more heavily loaded machines and at all temperatures including cold.

At Ariel, we have been refining our laundry detergent formulas for over 50 years, continuously looking for new ways to enhance cleaning effectiveness and delight our consumers. Our scientists are dedicated to exploring the latest scientific breakthroughs to improve our products.

What does this mean for your laundry?

In summary, smaller bottles and packaging do not mean you are getting fewer wash loads or worse cleaning results. Quite the contrary, thanks to years of scientific innovation, we are helping to create smarter laundry routines with products that are both powerful and more compact in size through product reformulation an downsizing.

So, the next time you encounter a compact detergent on the shelf, remember that it represents decades of progress, providing you with outstanding laundry results while saving space and reducing our environmental footprint.