Just like people, all products have an environmental impact for each stage of their life. A life cycle assessment (LCA) study analyses the environmental footprint a product makes on the planet across its entire journey, beginning at the sourcing of raw materials to its (usual and inevitable) disposal.

At Ariel, we feel an environmental responsibility to lead with innovation in the area of sustainability and we have been using LCAs for more than two decades to better understand our impact, help us progress on the road to sustainable innovation, and achieve our Ambition 2030 goals.

What is an LCA?

An LCA is a scientific methodology designed to help businesses measure and quantify the end-to-end environmental and economic impacts of a product, process, or service, and accounts for:

How raw materials were extracted,

The consumption of the resources involved in planning or designing the product,

Materials and energy used during manufacturing, packaging, and distribution,

Impacts from using the product,

Waste and pollution created throughout the process and at end-of-life.

Each product and category has an LCA that’s unique to them, yet they all follow the same four stages of the process:

Define the goal and scope of the life cycle analysis

Analyse inventory to get a full picture of all the elements/processes which contribute to the LCA (energy, waste, emissions, and so on)

Assess the impact of the inventory to help us understand the potential effects and damages

Interpret and make informed decisions based on the data.

What is Ariel’s life cycle analysis strategy?

Making smart and sustainable choices is not just an individual responsibility. We believe that brands should be responsible showing the way to a lower carbon emissions economy and lifestyle. We at Ariel are committed to a responsible laundry, hence our 20+ years-long history of using life cycle assessments to drive our innovations.

As they are steeped in data, informed by internal and external expert thinking and approved by credible and independent third parties, life cycle assessment studies allow us to see which areas of the life cycle are driving the most impact, paving the way for innovative sustainable solutions, such as producing laundry detergents capable of delivering impeccable cleaning even in colder temperatures and focusing on smart chemistry to boost performance whilst reducing environmental footprint.

You can read more about our Ariel Ambition 2030 goals here.

What can you do for the environment?

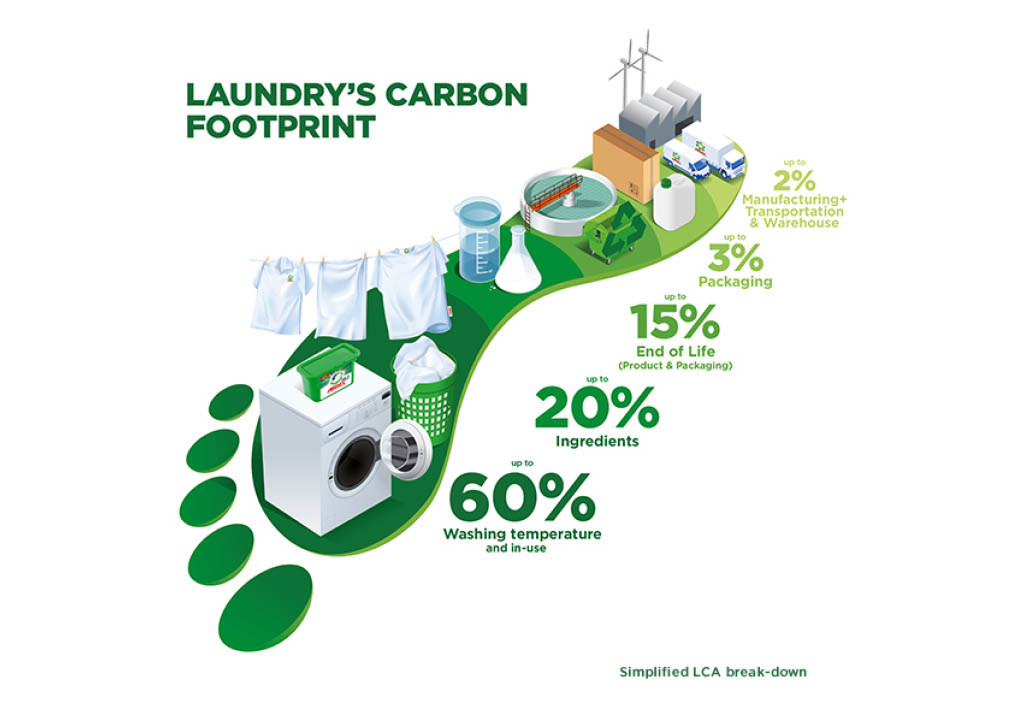

So, what are the key findings from Ariel’s life cycle analysis and how can we reduce laundry carbon footprint?

The in-use phase

When looking at Ariel’s LCA we found that this phase – physically doing the laundry in the home – accounts for up to 60% of the carbon footprint. The biggest contributor? The energy to heat the water for the washing machine.

Consequently, washing colder is the single biggest change we can all make to reduce the carbon footprint of doing our laundry. Research shows that turning down the temperature of our wash by just 10 degrees (from 40 to 30 degrees) can reduce the carbon emissions of the wash cycle by up to 35% So, every time you put on a wash and choose a lower temperature, you’re lowering your laundry carbon footprint AND your utility bills.

Read about the benefits of washing in cold water and join Ariel’s #washcoldchallenge today!

Our formula and packaging

This represents the carbon emissions generated by extracting the ingredients that make Ariel’s detergent formulas, as well as those required to make our packaging – and together these account for approximately only 20% (far behind the in-use phase) of Ariel’s carbon footprint

Ariel is committed to constantly finding more effective ingredients that deliver outstanding cleaning, while reducing the emissions required to source & formulate them.

Reducing the use of virgin plastic is also a key focus, such as increasing the amount of recycled plastic in our liquid detergent bottles & creating innovative packaging that reduces our plastic use. For example, our revolutionary SECURECLIC® box for our Ariel PODS® – is made from FSC Certified cardboard and is recyclable in accordance with local guidelines. Learn more here.

Production

This phase accounts for the carbon emissions coming from the manufacturing process, ie mixing the raw materials in the plant and then transporting the finished product to store shelves.

While this phase accounts for just 2% of Ariel’s carbon footprint, we have already taken several steps to minimise our footprint in this area.

We have identified that Ariel PODS® – as our most concentrated formula – also enable better transport efficiency, packing more product into fewer trucks on the road.

End of Life

This phase includes everything that follows the use of our product! At Ariel, we design our packaging to ensure that it can be effectively recycled in accordance with local guidelines at the end of life – and we are constantly looking at how we can reduce our impact further.

Today all our Ariel PODS® packaging is recyclablein accordance with local guidelines.

Related articles

How to save energy and help protect our planet

When doing your laundry, you may not be thinking about protecting the planet – but we are.

Great stain removal with quick wash even on cold wash

Sometimes you need clean clothes in a hurry. Sometimes you don’t have close to a full wash worth of dirty garments. Sometimes you just can’t wait for the normal cycle to finish.